Commercial print sector has entered a major transformation thanks to cutting-edge one-pass UV systems. This pioneering workflow produces rapid results while preserving excellent print resilience and sharpness. Via rapid UV-induced ink curing, one-pass UV printing obviates prolonged drying and multiple runs, trimming both cost and time.A standout benefit is its capability to output lively, enduring prints across multiple substrate types, e.g., plastics, metals, fabrics. The high resolution capabilities of one-pass UV printing result in stunningly detailed images and text, making it ideal for applications such as packaging, signage, and promotional materials. In addition, the technology’s reduced energy use relative to conventional printing fosters a more sustainable manufacturing workflow.

Commercial print sector has entered a major transformation thanks to cutting-edge one-pass UV systems. This pioneering workflow produces rapid results while preserving excellent print resilience and sharpness. Via rapid UV-induced ink curing, one-pass UV printing obviates prolonged drying and multiple runs, trimming both cost and time.A standout benefit is its capability to output lively, enduring prints across multiple substrate types, e.g., plastics, metals, fabrics. The high resolution capabilities of one-pass UV printing result in stunningly detailed images and text, making it ideal for applications such as packaging, signage, and promotional materials. In addition, the technology’s reduced energy use relative to conventional printing fosters a more sustainable manufacturing workflow. Deployment of one-pass UV technology reveals new possibilities for companies aiming to refine their printing output.

Deployment of one-pass UV technology reveals new possibilities for companies aiming to refine their printing output. Single-Pass UV Trends

High-throughput digital printing persistently aims for efficiency. Traditionally, this involves multiple passes of ink, leading to increased production times and potential for misalignment. Yet the arrival of Single-Pass UV is changing that landscape. Applying UV curing in one pass enables immediate ink set and great improvements in speed and alignment.Single-Pass UV creates striking color fidelity with high clarity and detailed richness. Therefore it fits high-demand contexts like volume packaging, large-format signage, and promo pieces where speed and visibility are crucial. With technology evolution, single-pass UV will likely foster additional advancements toward rapid, adaptable, and economical digital runs.

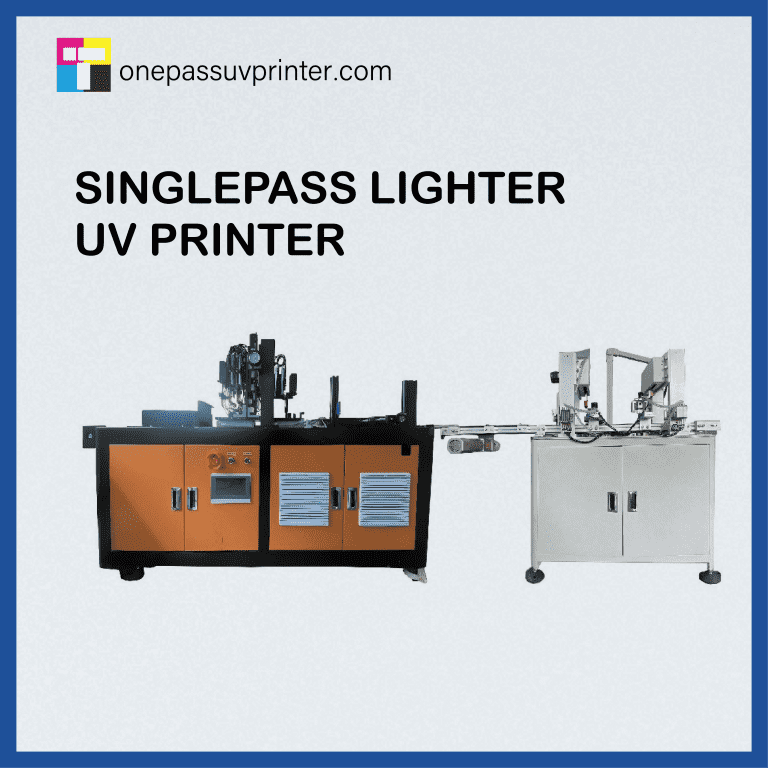

Single-Pass UV Printers: Precision at Pace

In the dynamic realm of printing technology, single-pass UV printers have emerged as a game-changer, redefining speed, precision, and efficiency. These machines utilize UV curing to harden inks at speed, facilitating exceptional production levels. With multi-color single-pass printing, these devices achieve exceptional resolution and brilliant color rendering. From custom short runs to mass commercial production, they support diverse applications, helping companies meet growing market needs.Optimize Your Print Production

Get ready to be amazed by the single-pass UV printer — a potent solution resetting industry benchmarks. This state-of-the-art printer uses UV curing in a single pass to secure exceptional print fidelity and resolution.- Experience vibrant colors with unparalleled precision

- Boost your production speed with rapid printing capabilities

- Expand new creative possibilities with a wide range of printable materials

Express UV Printing: Delivering Unmatched Efficiency

UV printing has revolutionized the graphics industry with its speed, precision, and vibrant colors. However, accelerated UV printing boosts those advantages, unlocking exceptional production efficiency. This technology utilizes specialized printers capable of outputting high-resolution images at incredible speeds. Because of instant curing and negligible drying, high-speed UV refines workflows to help companies satisfy even tight, heavy orders. Fast UV printing’s advantages include quality and application breadth as well as efficiency. It produces top-tier print results, long-lasting durability, and versatile application potential. From packaging through banner and label production to promotional signage, fast UV printing remodels business operations for innovation and agility.

One-Pass Production: The Ultimate Solution for Fast Turnaround Times

In our rapid world, speed matters most. When producing prints, rapid and efficient capabilities are required. One-Pass Print fills that gap. The system supports one-pass prints, eliminating repeat runs and reducing overall process time. One-Pass Print offers dramatically quicker turnaround times, recovering valuable time and capacity. Thus, enterprises of every scale can profit from One-Pass Print benefits. From marketing assets to vital paperwork, it provides on-time printing without compromise.Quality and Velocity Combined in Single-Pass UV

In modern manufacturing environments, efficiency reigns supreme. Manufacturers look for methods that deliver excellence without slowing production. Single-pass UV appears as a breakthrough merging fine inspection with instant curing. This process employs UV light to set inks and coatings instantly, achieving durable colorful finishes and minimizing cycle time. Inherent accuracy in single-pass UV yields impeccable products that meet high-quality thresholds. Benefits reach beyond mere quality and tempo gains. Single-Pass UV trims waste levels by eliminating lengthy drying, contributing to greener manufacturing.- Furthermore, the broad applicability of single-pass UV spans packaging, printing, and electronics production.

Advancing Digital Printing via Rapid UV

Printing continues to change under constant pressure for faster performance, finer precision, and novel technology. High-speed UV technology manifests as a major innovation uniting speed, precision, and operational flexibility. UV printing relies on ultraviolet curing to set inks immediately, removing long dry cycles and expanding printer capabilities. Rapid cure allows very high print speeds, substantially lowering production time and increasing overall efficiency. Also, UV ink formulations are highspeed uv printer highly durable and resist fading, scratching, and water, fitting diverse applications. From dynamic displays to long-lasting packaging, rapid UV printing is changing printing norms.- Gains

Fast Prints Now: One-Pass UV Printers Revolutionizing Output

In the fast-paced world of graphics/design/imaging, time is a precious commodity. Clients want quick turnaround and firms must provide excellent prints promptly. Enter one-pass UV printers, supplying disruptive solutions for today’s printing challenges. Advanced systems apply UV inks that cure immediately under illumination, removing drying wait times. The result? Instant prints with vibrant colors and durable finishes. Hence, one-pass UV systems see adoption across broad industry contexts. From retail and e-commerce to marketing, photography, fine art, and manufacturing, companies adopt instant printing. Applications include creating personalized products, producing custom signage, and generating eye-catching marketing materials. Advantages go beyond mere speed and efficiency. Single-pass UV offers exceptional color matching, crisp resolution, and wide substrate support suited to demanding tasks.- Also, single-pass UV reduces environmental impact by not using harsh solvents or VOCs.

- In summary, instant prints have arrived: with speed, flexibility, and high quality, one-pass UV printers are retooling the printing landscape for efficiency.

Streamline Production with Single-Pass UV

Tighten production process and realize greater efficiency via single-pass UV printing. This advanced tech lets you print vivid, high-res images directly onto many substrates in one pass, removing layered steps.- Achieve remarkable speed and lower production timelines.

- Improve overall output with speedier turnaround.

- Utilize UV ink’s accuracy and toughness for enduring vibrant results.

The Benefits of Single-Pass UV in High-Impact Printing

Single-pass UV has surfaced as a disruptive force in high-impact printing. The technique applies ultraviolet curing for inks, offering notable improvements over legacy methods. Firstly, single-pass UV printing provides unparalleled image quality due to its ability to produce highly vibrant colors and crisp details. Curing instantly removes drying delays, boosting productivity and shortening turnaround.- Moreover, the method creates hard-wearing prints that resist fading, scratching, and abrasion.

- To summarize, the blend of top image quality, higher productivity, and lasting durability makes single-pass UV ideal for high-impact printing needs.